www.auto-innovations.net

10

'22

Written on Modified on

Interplex News

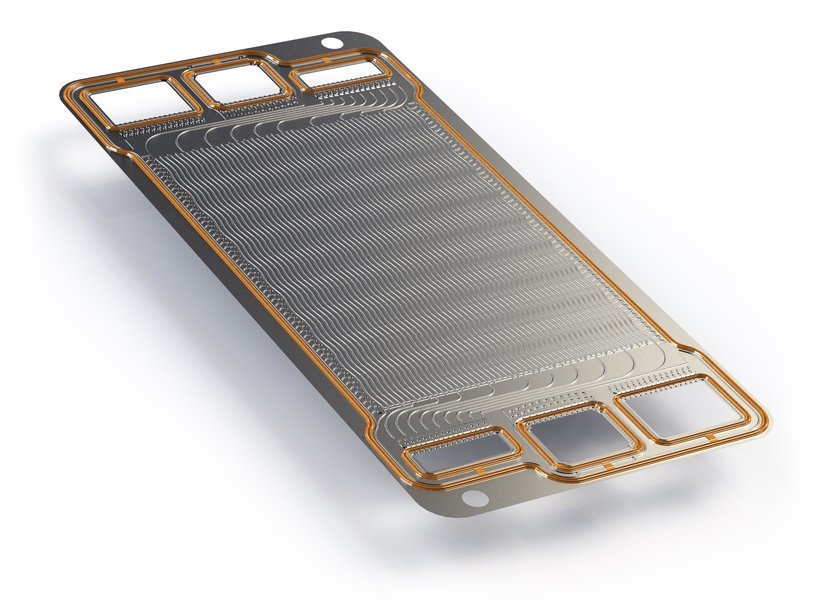

Latest Interplex bipolar plates feature innovative ultra-low contact resistance coating for heightened fuel cell efficiency

Precision manufacturing, with exceptional plate flatness, means better fuel cell stack structural integrity is realized and prevents leakage issues.

Interplex, leading specialist in advanced mechanical products for building a sustainable future, is using this year’s IZB (11-13 October, Wolfsburg, Germany) to highlight its engineering expertise in relation to e-mobility. Visitors to the show will be able to see the company’s latest bipolar plate (BPP) solutions for hydrogen fuel cells.

Fabricated from corrosion-resistant SUS316L stainless steel, the Interplex BPPs support an extensive operational lifespan of over 8,000 hours. They have thicknesses down to 0.8mm. Their ultra-low contact resistance (< 2mΩ·cm² at 1MPa pressure levels) helps to significantly boost the efficiency levels of the fuel cell stacks they are used in, and enables power densities to be raised.

Thanks to the precision stamping techniques employed, Interplex BPPs exhibit only ≤8% variation in the evenness with tight tolerances of flow channel thickness (across their active area), as well as offering enhanced plate flatness. These BPPs thereby deliver assured leak-tight operation and even power distribution across the entire surface of their plates. Likewise, advanced laser welding results in exceptional weld quality.

The high-speed stamping and coating procedures that Interplex has developed are key factors too. Via these, the company is able to reach industry-leading productivity figures - with physical vapor deposition (PVD) coating of plates being done in a fifth of the time compared to other suppliers. In addition, proprietary over-molding technology for attaching the silicone rubber gaskets to the BPP is done to elevated degrees of accuracy. It allows assembly problems to be minimized when stacking the BPP with a membrane electrode assembly (MEA).

Whereas, the majority of suppliers may have effective lab-based solutions, but then potentially lose some of the performance when ramping up to greater volumes, Interplex relies on the same process throughout. By applying this from initial prototyping all the way to mass production, customers can be certain that specification values remain consistently strong.

“There is no doubt that hydrogen fuel cells will be an essential element of future e-mobility strategies, alongside battery-powered electric vehicles, as society moves closer to the primary objective of zero emission transportation. The quality of the BPP products derived from our advanced manufacturing processes gives us a major competitive edge, enabling us to push the performance envelope while still keeping our products at attractive price points. Furthermore, the prolonged lifespans of our BPPs and the economies of scale we can achieve via state-of-the-art production workflows, translate into a lower overall cost of ownership,” According to Dr. Henrik Ljungcrantz, VP of Materials Science & Fuel Cell Systems at Interplex.

You can learn more about the Interplex BPPs by visiting Hall 1 Booth 1229 at IZB.

www.interplex.com