www.auto-innovations.net

09

'21

Written on Modified on

Stober News

Getting to qualification with a strong partner

The Formula Student Electric (FSE) was canceled last year due to the coronavirus. It will be held again in 2021. And Rennschmiede Pforzheim will be there. For the first time, the students will be at the starting line with an electric engine. Although the virus brought with it a host of challenges, the team kept to the tight schedule and presented its race car concept – even though they worked online. The team received extensive support from STOBER. The drive specialists supplied gear units, motors, drive controllers, and a great deal of expertise.

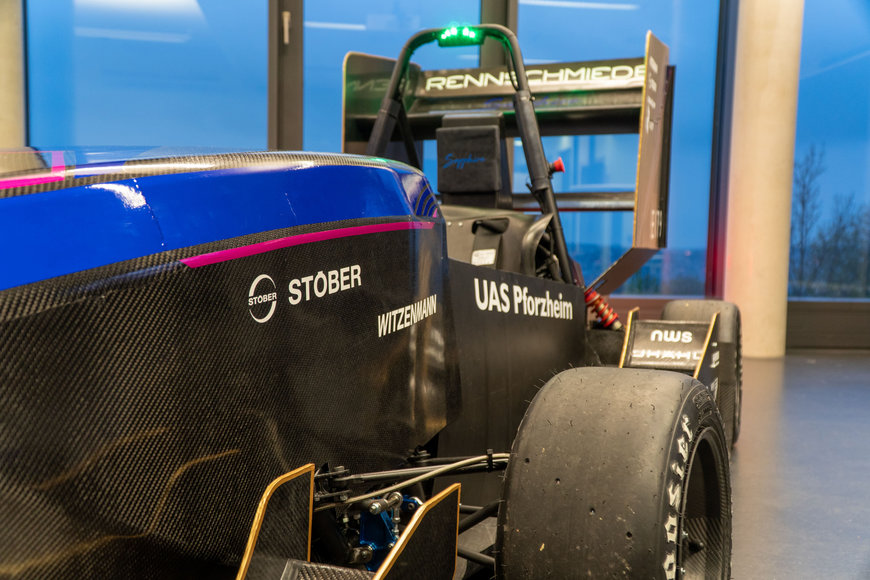

It bears the colors gold and blue and goes by the name RSP21 Sapphire. RSP stands for Rennschmiede Pforzheim, an initiative of the Hochschule Pforzheim college. Each year, Rennschmiede takes part in the Formula Student competition with a race car it develops itself. The team celebrated many years of success on the big racing tracks of the world with vehicles equipped with a combustion engine. In 2019, the racing team changed to the more demanding Formula Student Electric (FSE), and last year, it developed a purely electric race car, a technical challenge for the students from Pforzheim. Then the coronavirus pandemic happened. The students had to interrupt their work and the competition was stopped. That will not happen this year. The virus made it difficult for the team to stick to its tight schedule before the presentation at the end of April, as contact restrictions and lockdowns made meeting harder. But they did it. This was thanks in particular to support from sponsors and partners like STOBER from Pforzheim.

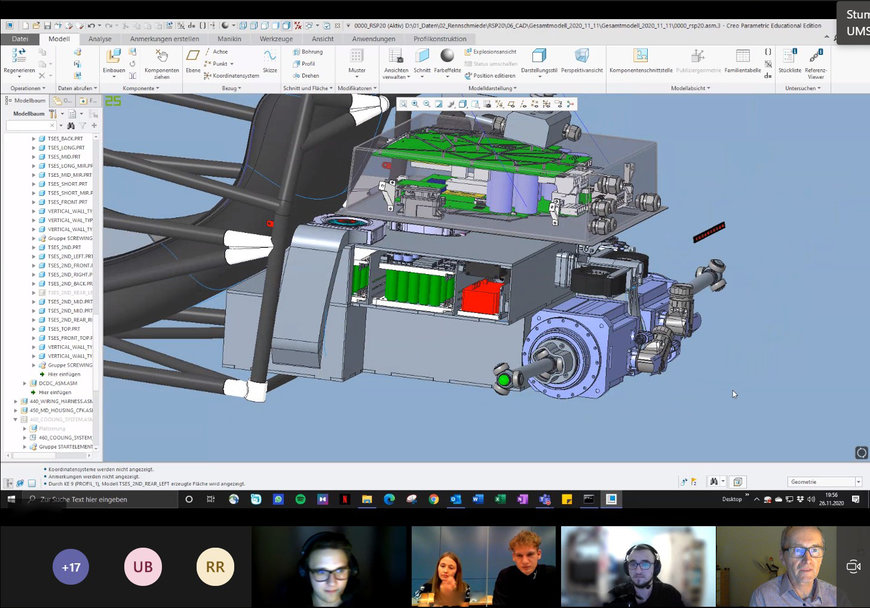

"Not only did we supply top-quality drive components, but our engineers also help the team out with their extensive expertise," says Dr. Florian Dreher, who supports the students on behalf of STOBER in matters of geared motors. As a rule, the specialist does not equip vehicles with its solutions. "For this reason, we worked with colleagues from the respective development departments to modify the motors and drive controllers slightly," says Stephan Scholze, Head of the Management Center for Electronics at STOBER. In order to build a competitive race car, maximum speeds of approximately 10,000 revolutions per minute were needed, for example, as well as motor ratings of 20 kilowatts. The drive specialist developed two high-speed synchronous servo motors for the rear axle for this purpose. "We also adapted the number of pole pairs to the required speed," describes Dr. Dreher. The delivered products also included two compact planetary gear units from the STOBER range with an i=7 gear ratio and two powerful SI6 series drive controllers. "We needed to design the controllers to be smaller in size so that they would fit in the streamlined body," says Scholze. The students saw to the control of these parts, which was no small feat.

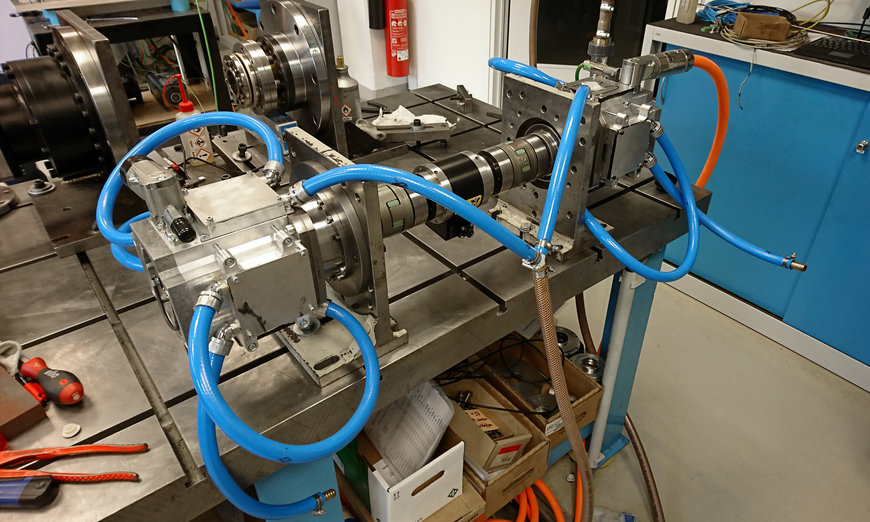

"We also made the drive controllers mobile," reports Scholze. After all, drive controllers are located in a control cabinet at STOBER customer facilities. In race cars, on the other hand, they must be in a housing that protects them against dirt and moisture. High-efficiency cooling for the geared motors is important so that overheating does not occur. The students developed a solution adapted to the vehicle that cools the motors and drive controllers in a water circuit. Metal foams in the cooling plates dissipate the heat even more efficiently. Extensive tests were and still are being performed in the test bay at STOBER, such as for acceleration of the vehicle or with regard to the route and movement profile on the Hockenheimring racing circuit.

The road to participation

"The students developed the concepts in close cooperation with our experts and implemented them on their own," says Dr. Dreher of the collaboration. After all, they know exactly what they need—how much torque is necessary at the rear axle, for instance, or where the components must be mounted. It is important that the motors and gear units for this task are optimally coordinated to each other. Together with STOBER, Rennschmiede also developed its own high-voltage battery with a nominal voltage of almost 520 volts.

Now, the task is to make the race car fit for qualification in the final race. FSE is a design competition where experts judge the teams in terms of concept, planning, and on the vehicle itself. Since all race cars are prototypes, they have to comply with a variety of safety measures and rules. If the teams meet these basic requirements with their cars, they can take part in the race. The judges check the high-voltage battery, the electrical safety, all safety-related components and accessories, and more. No operating fluid is allowed to leak and regulations for rollover protection must be met. The cars must also comply with a certain volume level and pass a brake test. Whether Rennschmiede will be allowed to compete in Hockenheim, demonstrating that its approximately 230-kilogram Sapphire is roadworthy, is decided on site. Currently, Rennschmiede is still on the wait list. As part of Formula Student, the team will definitely participate in the FS Alpe Adria event in Croatia, however. "Even qualifying for participation is an outstanding achievement for any team," says Dr. Dreher.

The race car must comply with a variety of safety measures and rules. Only then can it participate in the race.

Extensive tests were and still are being conducted in the test bay at STOBER.

Even though contact restrictions and lockdowns of the coronavirus pandemic made meeting difficult, Rennschmiede remained in close contact with all those involved.

Dr. Florian Dreher: "Not only did we supply top-quality drive components, but our engineers also help the team out with their extensive expertise."

Stephan Scholze: "We worked with colleagues from the respective development departments to modify the motors and drive controllers."

www.stoeber.de